Ein Artikel über das (Diamant-) Material der Abtastspitze

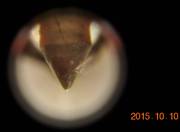

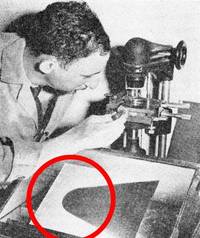

Bei meinen akribischen Versuchen, vor jeglicher Montage von Abtastsystemen erst mal die Beschaffenheit der Verrundung der Abtastspitze zu überprüfen - und zwar nachweislich mit einem datierten Foto dokumentiert zu prüfen - bin ich über manche Besonderheiten gestolpert, die "seltenst" beschrieben werden. Das fängt bei der komplizierten Beleuchtung einer Diamantspitze unter dem Mikroskop an und hört bei der Materialbeschaffenheit des Roh-"Diamant"- Materials auf. In dem folgenden - uralten - Artikel von 1950 wird das ausführlich behandelt, auf englisch natürlich.

.

Audio Engineering - FEBRUARY 1970, VOLUME 18, NUMBER 1

"The Diamond as an Industrial Material ......

With Special Reference to Phono Styli" (Reprint from 1950)

E. J. and M. V. MARCUS - The Tetrad Corporation, Yonkers, New York

* Reprinted from Audio Engineering, July, 1950. - Ein Nachdruck von 1950 !!!!

.

Editor's Note : (ein Vorwort des Chefredakteurs von 1970)

Writing in the North American Review in 1878 about sound reproduction from tinfoils (Aluminium-Folien), Edison asserted, that the use of "perfectly smooth stone point - diamond or sapphire - (would) render the record capable of from fifty to one hundred repetitions (das sind wiederholte Abspielungen), enough for all practical purposes."

This anticipation (Vorwegnahme) makes the work of E. J. and M. V. Marcus no less valuable (nicht weniger wertvoll). An enormous leap (Sprung, Hüpfer) was needed to make the dream of a diamond tip in every-man's pickup a practical reality.

.

- Anmerkung : Ab etwa 1975 gab es meines Wissens nach keine Pickup-Systeme (Abtaster) mehr ohne eine Diamant-Spitze/Nadel.

.

Rückblick auf die damaligen Materialien der Abtastnadeln

During the development of the phonograph industry in the 1920's and 30's, the predominant stylus material was steel. Not that all else had not been tried - there were even "cactus" styli which were supplied together with a little machine for sharpening after each play!

(Not long ago we were asked to re-record some rare instantaneous recordings made on aluminum blanks. We had to outfit a modern pickup with a Delrin tip to play them without scoring.)

But steel was king, and steel "needles", as they were called, came in all sorts of sizes and shapes, labeled "loud", "medium", and "soft", depending upon length and thickness.

They were readily replaceable by means of a thumb-screw. A packet of needles bore (langweilte imer wieder) the invariable warning, "For best results, use only once." No one ever paid attention to this admonition, which was merely a "gimmick" to promote the sales of needles.

.

Der Klang des Phonographs war sowieso miserabel

The sound was equally poor after the first as after the tenth playing, but we loved it. This magic of unlocking the sound in a groove has never disappeared.

Und auch kein Gedanke an die Form der Nadel bis 1937

In the early phonographs, no one seemed to worry too much about the geometry of the needle tip (Nadel-Spitze), which often was allowed to wear down to a chisel shape (herunter geschliffen zu einem dicken Meißel). To AES President Frederick Hunt goes the credit for demonstrating in 1937, that a smooth round tip was needed for proper groove reproduction, and that it ought to be supported by the walls of the groove, not by its bottom.

This idea acted as a powerful stimulant to the engineer to seek more durable styli and lighter-weight pickups, thus ushering in the era of "high-fidelity."

.

Die Saphir Nadel wurde Ende der 1930er entwickelt

In the late 1930's there was a growth of popularity of needles tipped with osmium (ein Hartmetall dem Platin sehr ähnlich) and other long-wearing alloys (standhaften Metallen). These gave way to sapphire, which with Linde's development of synthetic sapphire rod (Kristall-Stäbchen) became readily available.

For many years, sapphire dominated the pickup stylus scene, while the diamond was used only in pickups intended for broadcasting, such as the famous Western Electric 9A.

Bis Mitte der 1950er war ein Diamant-Stylus exklusiv teuer

Even as late as the mid-1950's diamond tips (Diamant-Spitzen) were beyond the reach (unerreichbar) of an average user. E. J. and M. V. Marcus can be credited with developing technology needed to make diamond styli available for the vast majority of the better pickups. Synthetic diamond chips also are playing a major role in the phonograph field.

It is fair to say that without the hardness, toughness, and durability of diamond, the elliptical stylus tip so popular today could not have become a reality. Reprinted below is the original Marcus paper (von 1950) relating to the use of early diamond styli in phonograph pickups.

B.B.B.

.

INTRODUCTION / Einführung in den Artikel von 1950 !!!

Upon examining the physical properties of groups of raw materials found (Roh-Material) in nature, we generally find small increments in the values of these properties.

Diamond is the outstanding exception to this rule in that it possesses durability and hardness values which exceed those of the closest comparable material - sapphire - by almost a hundred fold (das Hunderfache).

Diamond was recognized, even in antiquity, as possessing properties which have made it the most valuable material (except for some radio-active elements) on earth. These properties are durability, beauty, and rarity. For technical purposes, we are most concerned with the durability and hardness (Haltbarkeit und Härte) of diamond.

.

FORMATION AND OCCURRENCE OF DIAMOND

Diamond is pure crystalline carbon occurring sparingly in volcanic rock. Carbon, trapped in molten lava and subjected to tremendous pressure and heat crystallizes slowly to form diamond.

Although it is supposed that all diamonds were formed in this manner, only in South Africa do we actually find large volcanic intrusions or "pipes" (Einschlüsse und Flötze) containing deposits of diamond. Diamonds found in other parts of the world, the Belgian Congo, Brazil, India, Borneo and Australia, are found in alluvial deposits (angespülten Lagern).

The original volcanic sources remain undiscovered. Africa produces about 95% of the world's production, which has amounted to as much as 13,000,000 carats yearly (one carat = 0.2g).

The diamond-bearing volcanic pipes in South Africa were discovered accidentally between 1866-1888. These pipes, called blue ground, contain approximately 1 part of diamond in 15,000,000 parts of rock. The soft blue ground is mined, crushed and washed in troughs containing grease pans.

- Anmerkung : Es ist hier das erste Mal, daß der Begriff eines "shadowgraphs" auftaucht. Mein Ansinnen bei meiner Mikro-Fotografie, daß mich ja nur der "Umriß der Diamant- spitze" (oder besser formuliert : der Kontrast gegenüber dem Hintergrund) interessiere und nicht die plastische bzw. perspektivische Sicht, war also richtig gedacht.

Diamond, having a great affinity for oil or grease, sticks to the grease in the pans, and the stones are then collected and sorted.

CLASSIFICATION OF DIAMOND

There are various types of diamonds, and each has its specific application. The most valuable are the large, clear white, nearly flawless stones which are used for gem (Edelstein, Juwel) purposes. However, there are other types used for industrial purposes which possess the same physical and chemical properties but are unsuited (unbrauchbar) for "gem"s. Diamonds may be transparent, cloudy or opaque, clear white, or colored in various hues. The qualities of those diamonds suited for use as styli for audio equipment will be discussed in this paper.

Commercial diamonds are classified in several groups, two of which are:

- 1. Fine Industrials. - Diamonds unsuited for use as gem stones (Juwelen) due to small size, color or presence of small inclusions. In all other respects these stones are similar to the diamonds used for gem purposes.

- 2. Cleavages or Splints (Abspaltungen oder Splitter). - Chips cleaved from larger stones, usually during gemstone production. Lack the structural strength of small fine industrials. Sometimes employed for use as phonograph styli due to the comparative ease of fabrication.

.

FABRICATION OF DIAMOND STYLI

There are three principal methods of shaping diamond for industrial use, namely

- bruiting (zerkleinern),

- lapping (schleifen, polieren), and

- sawing (zersägen).

All other methods are usually variations of the three employing special fixtures.

All methods use diamond in some form to reduce the size or change the shape of another diamond. Diamond is the only material hard enough to cut diamond effectively. Large stones are sometimes cleaved along cleavage planes which can be determined by experts.

.

Bruiting

The bruiting operation is similar to freehand wood-turning in a lathe (die Drehbank, aber auch die Platten-Schneidmaschine), using a tool rest. The diamond to be worked on is placed in a special holder, called a dop, and put in the lathe chuck. A diamond tool placed in a long-handled holder and braced under the arm is worked against the spinning diamond in the lathe. This method is quite effective for rapid removal and rough shaping of diamond cones.

Lapping

This is the term used to describe the polishing of diamond surfaces and usually means the generating of a facet on a stone. Lapping is done on a rapidly spinning, porous cast-iron wheel which has been impregnated with a mixture of diamond powder and olive oil.

The stone is held in the dop and placed in a removable arm called a tang. It is then placed against the lap or wheel. Diamond crystallizes in the cubic system and has three equal axes intersecting at 90°.

Lapping can only be done along planes which have a definite relation of these axes. Under the usual lapping conditions, diamond will not polish or cut readily against the so-called grain or out of relation to these planes.

Therefore, in the polishing of diamond facets it is necessary to orient the stone properly to obtain the lapping direction. In polishing a cone and radius on a diamond, it is evident that rotating the diamond cone will encounter grain running in several directions and that conventional polishing methods can not be used.

It was found necessary to polish at extremely high speeds with very fine diamond powder to develop a high polish on the cone and radius of the stylus. The entire polishing apparatus must be free of vibration and exceptionally accurate.

.

Sawing

Diamond can be sawed with a thin phosphor-bronze saw charged with diamond powder and olive oil. Diamond-impregnated metal saws are also used. The diamond to be sawed is nicked with a sharp pointed diamond and moved into the saw. There are optimum sawing directions, depending upon the crystal structure of the stone.

CHEMICAL AND PHYSICAL PROPERTIES

Lavoissier discovered that diamond consisted of carbon when he burned diamond at high temperatures to form carbon dioxide, C02. Diamond can be burned in oxygen between 700° and 900° C.

Diamond is very resistant to strong acids (Säuren) and alkalis (Laugen). Concentrated solutions are frequently used to clean the stones. A mixture of sulphuric acid and potassium bichromate can oxidize diamond slowly at 200° C. Diamonds are cleaned of foreign matter from the mines by storing in hydrofluoric acid. They are cleaned after processing by cocking in a concentrated solution of potassium hydroxide, usually followed by a second cooking in sulphuric and nitric acid. Aca regia is sometimes used to clean diamonds.

Remarkable as diamond is in its resistance to chemical action, it is even more outstanding in its amazing physical properties. The compact arrangement of the carbon atoms in the diamond has resulted in an extremely durable and hard material.

Table I lists the physical properties of diamond compared with alternative materials.

Table I.

Physical properties of diamond and alternative stylus materials

| die bewertete Eigenschaft | Diamond | Alternative Material |

|---|---|---|

| Resistance to abrasive wear/Abnutzung (Rosiwal) | 90,000 | Sapphire 1.000 |

| Wear resistance, path of turning tool (Grodzinski) | 1,250 | Carbide 12.5-20.5 |

| Ratio of time required to saw given area (Grodzinski ) | 100-300 | Sapphire 1.0 |

| Indentation hardness (Knoop) | 6000-6300 | Sapphire 1600-2000 |

| Initial bearing friction (Shotter) | 0.70 | Sapphire 1.13-1.60 |

| Breaking load on a radius (Schuler) | 25 | Sapphire 5 |

| Compressibility (Williamson) | 0.18 | Sapphire 0.38 |

| Surface Finish (Kayser) | Better than any | other material |

| Index of refraction-sodium | 2.419 | Glass 1.426 |

| Dispersion | 2.465 | Glass 1.532 |

Note: Moh's scale (1820) which gives comparative but not quantitative hardness values of gem materials has been omitted. Moh listed gem materials in order of ability to resist scratch marks.

.

"How hard is diamond?"

The question is frequently asked, "How hard is diamond?" This is a difficult question to answer, since hardness is a composite property embracing many characteristics. When one thinks of something as being hard, one is at the same time thinking of a number of properties such as resistance to wear, ability to resist indentation of a sharp point and non-compressibility.

For example, if we say a piece of wood is hard, we mean it cannot be sawed or chopped easily, or that it is difficult to drive a nail into it. If we say a piece of metal is hard, we may mean that it cannot be filed, sawed, or bent readily.

.

Therefore, an answer can only be given in terms of the job being performed by the given materials. Numerical results for comparative hardness and durability of materials will vary from one set of conditions to another. However, a glance at the table of comparative physical properties shows that diamond has a tremendous advantage over its next-best alternative material in resistance to abrasive wear (Abschliff), breaking load on a radius (Traglast bei Rundungen), indentation hardness (Oberflächenhärte), and compressibility (Druckfestigkeit).

.

PHONOGRAPH STYLUS WEAR (Abnutzungs-) TESTS

Tests have been conducted to determine the comparative durability of various stylus materials. (Der Artikel stammt aus 1950 !!, als die 33er und 45er Vinylplatte in Mono gerade anfing, den Markt umzukrempeln))

When a playback stylus touches a record groove, only a small area of the stylus tip actually makes contact with the groove walls. The pressure (Drucklast) per square inch (also pro Fläche) may amount to several tons.

The dynamic forces acting on the stylus tip are several (das ist schon einiges) and severe (bedrohlich). Hard record materials containing abrasive (Schleifmittel wie bei der Schellackplatte der Stein-Staub) have a greater ability to wear (verschleißen/abnutzen) styli, but soft record materials often become imbedded with abrasive particles (harte Staubpartikel) which also can cause rapid stylus wear.

Stylus wear is rapid at first (am Anfang am stärksten), and then, as the contact area becomes larger (also wenn die Rundungen angeschliffen sind) and the pressure per square inch decreases (der Pressdruck nachläßt), wear continues at a slower rate.

This effect is noticed with new clean records: however, as records become worn (sind verschlissen) and the grooves become progresively loaded with abrasive particles (das ist der Staub), the rate of stylus wear may continue at a comparatively rapid rate.

.

"Weiche" Nadeln hätten weniger Rillenverschleiß zur Folge ??

The softer stylus materials (das weichere Nadelspitzen-Material) have a great tendency to load the record grooves with abrasive particles, as shown by G. A. Briggs [1] (Briggs war aber ein Lautsprecherspezialist).

It is a fallacy (Irrtum) that styli made of soft materials (weichem Material) cause less record wear (weniger Rillenverschleiß). Brigg's photomicrographs show steel flakes imbedded in the grove walls after only one playing of a new shellac disc by a steel needle.

Another photomicrograph shows a "fibre" needle (sorry, was ist das für eine Nadel ?) completely abraded (abgeschliffen) after one playing. These conditions lead to excessive record wear and poor response.

- Anmerkung : Das Letztere ist nicht ganz schlüssig, weil die oben referenzierte Schellack-Platte zu über 65% aus gemahlenem Stein (Basalt oder Granit) besteht, dann noch mit etwa 10% Ruß gemischt wurde und dann das Harz - der Schellack - als Bindemittel hinzukam.

.

Unsere Tests mit Vinyl Schallplatten (alles etwa 1950)

(das kann aber so gar nicht stimmen)

Our tests were conducted on Vinylite records, both standard groove 78 rpm and microgroove 33 1/3 rpm, using three stylus materials:

- diamond,

- sapphire, and

- osmium.

The conditions observed for all styli under test are summarized in Table II.

.

- Anmerkung : Da kommt jetzt etwas, das ich nicht verstehe. Bislang ist mir und meinen Freunden noch nie eine 78er Vinyl-Platte untergekommen, weder in einer Publikation noch in Natura. Also wovon redet der Autor ?

.

Table II. Test conditions for stylus wear tests.

| Standard Groove | Microgroove | |

|---|---|---|

| Record material | 10" Vinylite | 12" Vinylite |

| Record player | Garrard changer | Webster 3 speed changer |

| Cartridge | Astatic L70 | G.E. RPX-041 |

| Pickup weight | 1 1/4 oz | 8g |

| Radius of stylus | 2.5 mil | 1.0 mil |

.

- Anmerkung : Ich vermisse hier die eigentliche Auflagekraft. Es ist zwar das Gewicht des Abtast-Systems angegeben, aber das hatte mit der Auflagekraft der Nadel nichts gemeinsam.

.

Alle Tests sind 12 Mal wiederholt worden

Test methods were made to conform to the severe playing conditions usually encountered with home-type equipment, and both tests were repeated twelve times to eliminate the possibility of error.

Die Abnutzung von Nadel und Rille nach 50 Stunden

The results of the standard-groove test (auf der 78er Schellack-Platte ???) showed, that after 1.000 plays, or approximately 50 hours playing time, wear on both the sapphire and osmium tips were very severe (bedrohlich, heftig).

Considerable (erhebliche) wear (Abnutzung) was noticed as early as 100 plays (beim 100. Abspielen). There was complete conformity (Angleichung der Nadelspitze) to groove shape (an die Rillenform) after 1000 plays. The diamond stylus did not show any wear after 1000 plays (keinerlei Abnutzung).

.

Schatten-Fotografien immer nach 100 Abspielungen

Shadowgraphic tracings were made after each 100 plays and showed the progression of wear on the sapphire and osmium tips. Photomicrographs were taken of the stylus tips after 1000 plays. Two views were photographed, one parallel to the groove position, the other perpendicular to the groove.

Superimposing the osmium shadowgraph tracing over the sapphire tracing, we found the same amount of wear for sapphire at 1000 plays as for osmium at 400, or a 10:4 ratio.

Fast keine sichbare Abnutzung beim Diamanten

Since the amount of material revoved from the diamond was so slight as to escape notice at 500 times magnification, the ratio of wear could be written Diamond 00, Sapphire 10, Osmium 4. However, eventually even the diamond will begin to show wear.

The results of the microgroove test were rather surprising. We found that after only 15 plays or 5 3/4 hours playing time, both the sapphire and osmium tips were very badly worn, and the test was stopped at the time. Again the osmium wore out faster than the sapphire.

Photomicrographs and tracings were made at the completion of the test. The diamond showed no sign of wear after 15 plays. The microgroove diamond was continued in use for a total of 100 plays or 37 hours. A slight flat was noticed on the diamond at the end of 37 hours.

Abnutzung bei Micro-Rillen schneller als bei 78er Rillen

Apparently, stylus wear is far more rapid on micro-groove than on standard groove records. A rough estimate is about three times faster. The rate of wear of the 1.0 mil osmium and sapphire styli caused by microgroove playing is so rapid as to make these materials unsuited for continuous use on microgroove records.

To return now to the hardness values given in the table, we can see that it is necessary to conduct tests under the conditions of use before hardness values can be assigned to any materials.

If we could accurately weigh the stylus tips before and after the tests, it is quite certain we would find a difference between the diamond and sapphire in excess of the 90:1 ratio given by Rosiwal.

Über die Abnutzung von Diamant und Rille

According to Ridgway and Eppler, the differences in relative mechanical corrosion hardness become smaller as the hardness of the material used for the corroding or abrading increases. They used a sand-blast technique in determining the resistance of various materials to corrosion. As the hardness of the powder used for the sandblast was increased in going from quartz to sapphire to silicon carbide, the differences in the hardness values for the test materials became smaller.

We observed corresponding results in our stylus wear tests. As we have already shown, the wear ratio between diamond and sapphire when played on Vinylite records is far above the Rosiwal 90:1 ratio, while this difference is not quite as great when these materials are used on shellac records.

Other results of our stylus and record wear tests showed that wherever there was excessive stylus wear it was always accompanied by excessive record wear. The badly worn styli are unable to track properly and have a tendency to chop off the high-frequency crests in the grooves.

It was observed that stylus pressure, pick-up arms, and cartridges have a great effect on stylus and record wear. Considerable variation in rate of stylus wear was noticed in making wear tests on different types of equipment.

Die hohe Auflagekraft bei den Profis ist ungünstig

For example, one professional arm caused 1.0 mil styli to wear out about five times faster than did other arms designed for amateur use. (Wir sind noch in 1950 und die Plastik Tonarme der "amateurs" hatten vielleicht 5 Pond Auflagegewicht, die Metalltonarme der Profis vielleicht 15 Pond oder mehr.)

Quality of response deteriorates (verschlechtert sich) gradually as stylus wear (die Abnutzung) increases (zunimmt). This deterioration is noticed more readily on good quality audio equipment. (Diese Verschlechterung wird auf hochwertigen Musik-Anlagen viel leichter wahrgenommen.)

On hometype equipment, with its narrower (geringeren) frequency range, stylus wear is usually not noticed audibly until it has become very bad.

The gradual wear over a long period of time occurs slowly, and therefore the listener does not readily notice the change. He cannot remember how his equipment sounded six months before when the stylus was new. This has the unfortunate effect of causing excessive record wear by continuing the worn stylus in use.

.

* Reprinted from Audio Engineering, July, 1950. - Ein Nachdruck von 1950 !!!!

.

REFERENCES

.

- 1. G. A. Briggs, Sound Reproduction (Wharfedale Wireless Works, Bradford Road, Idle, Bradford, Yorkshire, England).

- 2. W. F. Eppler, "Relative Mechanical Corrosion Hardness of Synthetic Corundum." Industrial Diamond Review, 121 (June 1945).

- 3. P. Grodzinski, "Notes on the Cleaving and Sawing of Diamond," Mineralogical Magazine (Sept. 1944).

- 4. J. F. Kayser, Industrial Diamond Review 4, 2 (1944).

- 5. F. Knoop, Industrial Diamond Review 1, Research Paper 1220, 292 (1939).

- 6. R. R. Ridgway, "Hardness Values for Electrochemical Products," Trans. Electrochem. Soc. 63, 369 (1933).

- 7. A. Rosiwal, Akad. d. Wissenschaften (Wien, 1893, No. 11), and 1917.

- 8. Schuler and Dimpker, Zeitschrift f. Instrument-kunde 55, 63 (1935).

- 9. G. F. Shotter, Meter and Instrument Jewels and Pivots (2nd report, British Electrical & Allied Ind. Res. Assoc, 1944), p. 110.

- 10. A. Williamson, /. Franklin Institute 193, 491 (1922).

.

AES - FEBRUARY 1970, VOLUME 18, NUMBER 1

.